Subaru Breakdown

August 26, 2001

A couple of weeks after our trip to the Southwest Lolli and I headed up to Seattle to visit our relatives.

We had a nice visit and returned home with another 2,600 miles on the odometer, trouble free motoring all the way, except it looked like my water pump might be leaking. One morning there was a drip coming from the timing belt cover but after the engine was warmed up and the coolant was under pressure, the drip stopped.

Anyway, we made it home and the next morning when I left to go to work, the engine started up with a loud rattle sound which settled down within seconds. I shifted into reverse and backed up about 10 feet when the Vanagon suddenly stopped and the engine died. I thought I had backed into something. I hopped out and took a look and nothing was there!! I hopped back into the Vanagon and tried to start it. The starter would not turn it over. Oh oh!

A friend and I tried to push start it. We got it rolling and I popped the clutch in 2nd gear. The rear tires slid in the gravel!!

The engine was frozen. Nothing left to do but pull the engine and find out what happened.

|

Oh boy, here we go. My friend Eddie gets into position.

|

This is my engine removal invention. A 4X4 cribbed up on several pieces of wood. A nylon rope looped over the 4X4 and down to the lifting points on the Subaru engine. We undo the bolts on the cross member and then, by lifting or pressing down on the 4X4 we remove the wood blocks, one by one, and let the engine down. Part way down we run out of blocks, support the engine from below, untie the nylon rope, add more blocks, retie the rope and continue lowering the engine to the ground. The cross bolt is still in place at the transmission nose. Once the engine is on the ground we move under the Vanagon and remove the cross bolt and let the tranny down. Then slide the engine and tranny out from under the Vanagon.

|

Well, here we are. We pulled the crank pully, removed the belt tensioner and then removed the timing belt. The spark plugs have been removed. We can turn each cam freely with only the valve springs offering resistance. The heads and valve train seem okay. We then turn the crank and it is frozen in one direction. We turn it the other direction and it goes part way and then gets harder and harder to turn and then I can't turn it any further.

August 27, 2001

|

The oil pan, pick up tube and splash shield have been removed. This is the view.

|

The only thing we have noticed so far that seems to be out of order is the fact that the crank counterweights have been rubbing against the bearing support castings on both sides. The black arrow, above, shows one of the wear areas; part of the crank counterweight is seen just to the right of the case split line. One list member mentioned this might be a problem known as "end play". I still don't see how this could happen "all of a sudden".

|

Elsewhere, everything is beautiful. This is the valve train. No gunk. For having 112,000 miles on the engine it sure is clean.

|

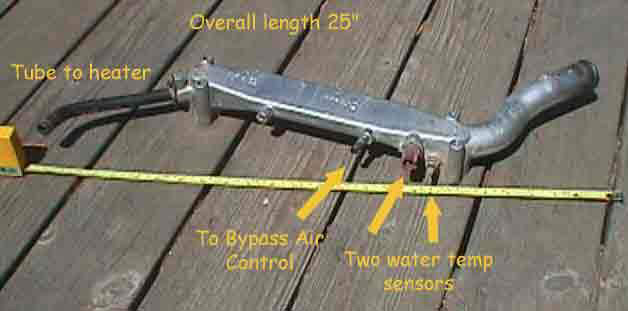

I removed the intake manifold and here is the water casting that some folks have reversed.

|

Just for interest I reversed the casting and set it in place putting one bolt in the hole on the left side. You can see that the casting hits the rear of the engine casting and the bolt holes on the right side of the casting are about half an inch off requiring carving away some of the engine casting for clearance.

|

Here is a close up of the problem area.

|

|

I will not be reversing this casting. I like the original routing so I can use my burp tank. Since I have all my plumbing and wiring harness already installed I will just stay with things as they are.

|

There has been an ongoing discussion on the list about the problem of using copper pipe with an engine that is aluminum. I used copper pipe for my conversion and have used the original charge of phosphate free coolant for 44,000 miles. Above is an image of the inside surface of my water jacket by one of the cylinders. It is as clean and smooth as a babies butt. End of discussion as far as I am concerned!!

Someone mentioned the problem prone Subaru oil pump.

|

Here is mine. The hole in the center slides over the crank. The gears draw the oil in one side and force it out the other. Seems simple and trouble free to me.

And, as for the shortened oil pan controversy.

|

Yes, ugly! You can see the gray goop I used to seal my shortened KEP pan. On the pan itself you can see residue dirt from the Southwest and Seattle! Anyway, notice that the oil pick-up tube is now sitting on the bottom of the pan. You will notice that if it was bolted up to the bottom of the engine there would be about an inch of clearance between the bottom of the pick-up tube and the pan bottom. The pick-up tube is a shortened Subaru original and has a 2 - 3/8" diameter base with a screen across the bottom. I use Castrol 10w40 oil and with a fresh oil filter it takes 4 quarts of oil when servicing. I do not believe I have ever starved the engine of oil when making those high speed turns all us Vanagon drivers are noted for!!

Meanwhile, I need to get a 12 point socket to remove the bolts to split the case.

August 28, 2001

I loaded the block up and hauled it to the local garage. Using their tools and finding a few more hidden bolts I finally got the case split. I discovered that the pistons can not be pulled down and out of the cylinders, no, I had to remove the nuts on the rod caps to be able to finally get the case all the way apart.

|

Finally, the problem was discovered.

|

One of the connecting rod bearings had "spun". It was "doubled up" and jammed.

|

Here are the upper and lower halves of the bearing. Obvious galling.

By the way, the bearing that spun was on the piston closest to the transmission.

The other connecting rod bearings also show galling. Obviously I did loose oil pressure at some time. In thinking about it I remember I did notice my oil pressure light come on one time when driving down a steep hill. How long it had been on I don't know. It is a two mile hill with some steeper parts. The light went out before I reached the bottom of the hill. I checked the oil and discovered I was a quart low. That was before our 2,600 mile trip to Seattle. That is the only time I have ever notice the oil light coming on but maybe that was enough to set up my problem. During the past month or so I have had a rattle sound when starting up in the morning.

In fact the rattle first showed up during our trip to the Southwest after my Vanagon got dropped during the ferry boat crossing. Who knows what happens to a running engine when it gets a hard knock like that. If that started the problem it is way to late to complain about it now.

I am going to continue using the KEP shortened pan but I will start making sure I am at the full mark on the dip stick or a bit above. I am also going to invest in a oil pressure gauge.

Well, bummer. I hope something was learned from my experience. I believe Subaru engines are bullet proof but they obviously do need oil pressure at all times! And what engine doesn't?

August 30, 2001

Click here to continue the story.