|

January 3 - 9 1999 Well, here it is, 1999. Can we complete the Lantern before the Y2K problem strikes? We hope so. If the Y2K problem does arise we could re-install the oil vapor light, along with the original clockworks and the 100 year old Lighthouse would be operational for those ships floundering around with their computers, GPS, and radar units out of whack! Well, enough dreaming! We start this week by putting in the last two deck plates.

Deck plate #7 being lowered into place with the help of the Jingjiang fork lift.

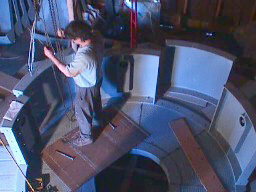

January 6th. After deck plate #8 is lowered and secured we then start bringing the Parapet castings over and into place.

Now and then we check our copy of the original 1890 blue prints to make sure we are doing things right!

Each Parapet casting is lifted with the chain-fall in order to allow room to apply Vulcem sealant to the mating surfaces and then lowered into place and bolted to each-other and to the deck plate floor by using, hot dipped, galvanized, 2" X 5/8ths bolts.

After getting the Parapets and the door frame together and adding a couple bronze window sashes, temporarily. Holy smokes! - it is starting to look like a Lantern house! Could the end of this restoration project be in sight?

Mike Stenburg stopped by to see just where all those bronze parts, that he "glass beaded" in his shop in Fort Bragg, fit.

Meanwhile, the cleaning of the Fresnel lens continues. This part, that Ginny Frundt is looking through, is call the "Bulls eye". There are four "bulls eyes" in the Fresnel lens; each 90 degrees apart from each other.

January 8th. Yippee, the crates of new window glass for the Lantern arrive.

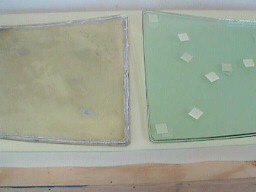

We unpack several windows and discover two things. 1. They are a wee bit too large to fit the

bronze window sashes. This image shows two sets of windows. Two original windows, one on top of the other, on the left and two new windows, one on top of the other on the right. The little white squares on the windows on the right are foam pads that separated the glass during shipping. The green tint is obvious. A possible reason for the green tint is that the old window are made of plate glass, the new windows are made of laminated safety glass. Since new laws require safety glass maybe we will have to live with it. As far as the window size problem... Each window seems to be about a 1/16th of an inch too large. The inner and outer laminate seem to be mis-aligned. It is possible to use a belt sander to trim each window to fit its bronze sashes but it can be done. I am sure there will be a big meeting of the minds come Monday! Oh boy! |